Qalab

| Jirka | Birta |

| dhame | Zinc Plated |

| Mandrel | Birta |

| dhame | Zinc Plated |

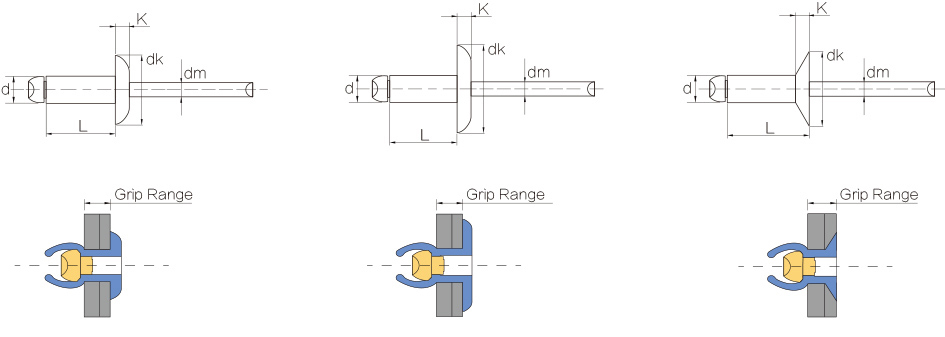

| Nooca Madaxa | Dome, CSK, Flange Weyn |

Tilmaamid

| D1 NOM. | QODON MAYA. & QODOBKA QOFKA | FANKA.CODE | XABSADA | L(MAX) | D NOM. | K MAX | P MIN. | SHARE LBS | Kacsan LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0.876-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 1000 4450N | 1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| SS812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Codsiga

birta furan ee indhoolayaasha indhoolayaasha ah ma aha oo kaliya sahlan isticmaalka, waxtarka sare, qaylada hoose, waxay yarayn kartaa xoojinta shaqada iyo sifooyinka kale, laakiin sidoo kale isku xirka cidhiidhiga.Rivetsyada birta ah waxaa loo qaybin karaa rivet madaxa qubbad, rivets countersunk iyo rivet madaxa flange weyn.Awooda xajinta iyo dhogorta ee birta indhoolayaasha ah ayaa aad uga sarreeya rivets aluminium caadiga ah.Waxaa si ballaaran loo isticmaalaa warshadaha, dabooli kara baahida codsiga xoogga sare.

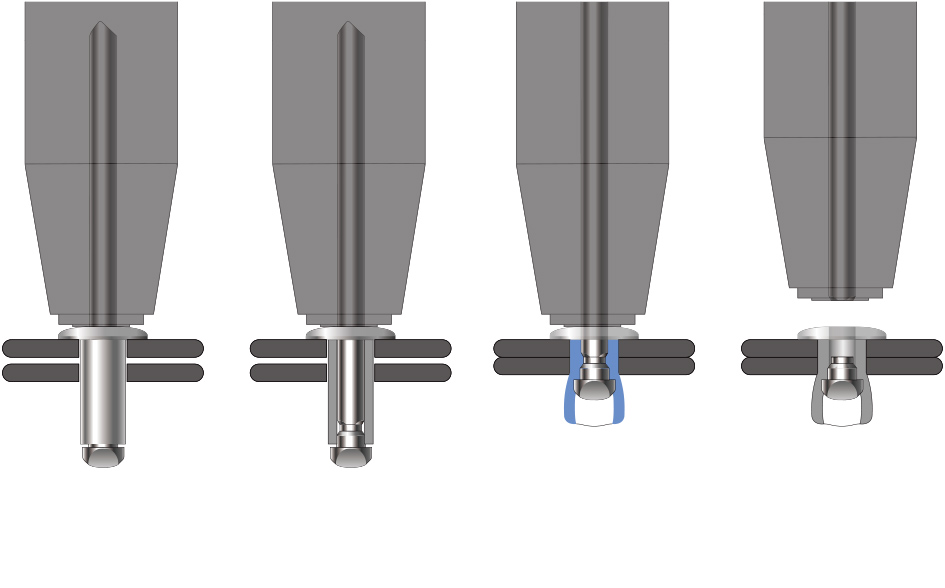

Dhibaatooyinka iyo sababaha marka la isticmaalayo pop rivet:

4.Rivet-ka pop-ka ayaa la soo dhex maraa: Maandooriyaha rivet si buuxda ayaa loo soo saaray jeexjeexa, manderkuna wuu jabay.Riveting ka dib, ka tag godadka madhan ee jeexjeexa.

Sababaha soo jiidashada dhex waa: xiisad mandrel rivet aad u badan;dhexroor yar oo koofiyadaha mandrel;qalabka jilicsan ee jilicsan;dusha sare ee daloolka gudaha ayaa ah mid aad u saliidaysan.

5. Ka bood madaxa ama durbaanka oo aan ku filnayn: Marka la jiido rivets, xudunta udubdhexaadka ah ayaa si buuxda u soo baxda, ama rivetku ma bararo.

Sababaha dhacdadan ayaa ah: xakamaynta xoogga xajinta ayaa aad u hooseysa marka cididaha ciddiyaha la sameeyo;Jirka qulqulaya waa sarreeyaa (aan sinnayn;

6. Is deji ka dib riveting: Ka dib riveting, jirka riveting waa dabacsan godka workpiece.