Qalab

| Jirka | Aluminium (5056) ● | Birta | Bir daxal laheyn | ||||

| dhame | La tolay | Zinc Plated | La tolay | ||||

| Mandrel | Aluminium | Birta ● | Bir daxal laheyn | Birta | Aluminium | Birta | Bir daxal laheyn |

| dhame | La tolay | Zinc Plated | La tolay | Zinc Plated | La tolay | Zinc Plated | La tolay |

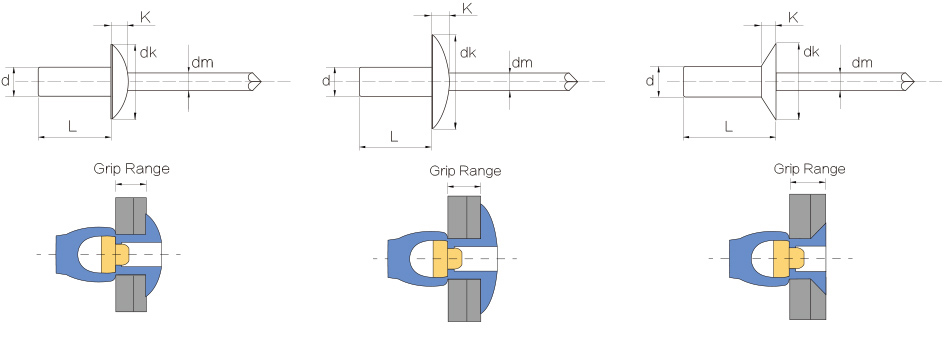

| Nooca Madaxa | Dome, CSK, Flange Weyn | ||||||

Tilmaamid

| D1 NOM. | QODON MAYA. $ dalool cabbirka | FANKA.CODE | XABSADA | L(MAX) | D NOM. | K MAX | P MIN. | SHARE LBS | Kacsan LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm | #30 3.3-3.4 | ASF41 | 0.020-0.062 | 0.5-1.6 | 0.297 | 7.5 | 0.238" 6.0 | 0.050" 1.27 | 1.06" 27 | 240 1070N | 280 1250N |

| ASF42 | 0.063-0.125 | 1.6-3.2 | 0.360 | 9.1 | |||||||

| ASF43 | 0.126-0.187 | 3.2-4.8 | 0.422 | 10.7 | |||||||

| ASF44 | 0.188-0.250 | 4.8-6.4 | 0.485 | 12.3 | |||||||

| ASF45 | 0.251-0.312 | 6.4-7.9 | 0.547 | 13.9 | |||||||

| ASF46 | 0.313-0.375 | 7.9-9.5 | 0.610 | 15.5 | |||||||

| ASF48 | 0.376-0.500 | 9.5-12.7 | 0.735 | 18.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | ASF52 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.312" 7.9 | 0.065" 1.65 | 1.06" 27 | 350 1560N | 480 2140N |

| ASF53 | 0.126-0.187 | 3.2-4.8 | 0.437 | 11.1 | |||||||

| ASF54 | 0.188-0.250 | 4.8-6.4 | 0.500 | 12.7 | |||||||

| ASF55 | 0.251-0.312 | 6.4-7.9 | 0.562 | 14.3 | |||||||

| ASF56 | 0.313-0.375 | 7.9-9.5 | 0.625 | 15.9 | |||||||

| ASF58 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | ASF62 | 0.020-0.125 | 0.5-3.2 | 0.406 | 10.3 | 0.375" 9.5 | 0.080" 2.03 | 1.06" 27 | 500 2230N | 690 3070N |

| ASF63 | 0.126-0.187 | 3.2-4.8 | 0.468 | 11.9 | |||||||

| ASF64 | 0.188-0.250 | 4.8-6.4 | 0.531 | 13.5 | |||||||

| ASF66 | 0.251-0.375 | 6.4-9.5 | 0.656 | 16.7 | |||||||

| ASF68 | 0.376-0.500 | 9.5-12.7 | 0.781 | 19.8 | |||||||

| ASF610 | 0.501-0.625 | 12.7-15.9 | 0.906 | 23.0 | |||||||

| ASF612 | 0.626-0.750 | 15.9-19.1 | 1.026 | 26.1 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | ASF82 | 0.020-0.125 | 0.5-3.2 | 0.445 | 11.3 | 0.500" 12.7 | 0.100" 2.54 | 1.25" 32 | 900 4000N | 1100 4890N |

| ASF84 | 0.126-0.250 | 3.2-6.4 | 0.570 | 14.5 | |||||||

| ASF86 | 0.251-0.375 | 6.4-9.5 | 0.695 | 17.7 | |||||||

| ASF88 | 0.376-0.500 | 9.5-12.7 | 0.820 | 20.8 | |||||||

| ASF810 | 0.501-0.625 | 12.7-15.9 | 0.945 | 24.0 | |||||||

| ASF812 | 0.626-0.750 | 15.9-19.1 | 1.070 | 27.2 | |||||||

| ASF814 | 0.751-0.875 | 19.1-22.2 | 1.195 | 30.4 | |||||||

| ASF816 | 0.876-1.000 | 22.2-25.4 | 1.320 | 33.5 | |||||||

Codsiga

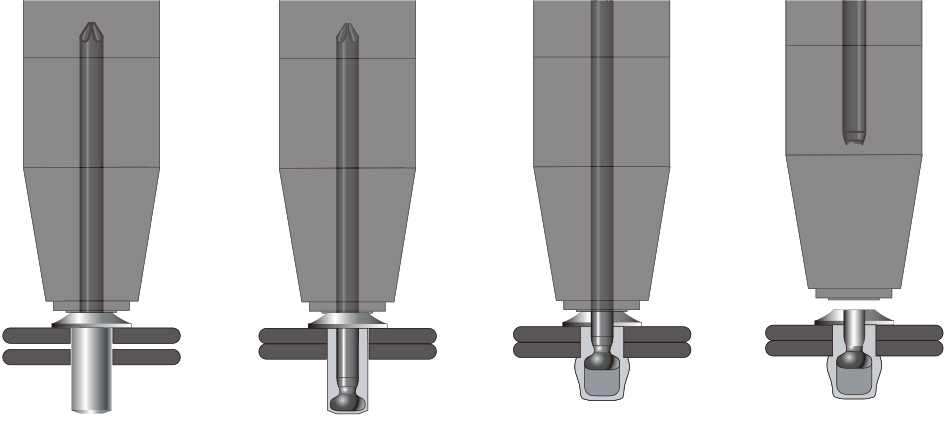

Rivet-ga pop waa nooc ka mid ah rivet-ka loo isticmaalo qulqulka hal-dhinac ah, laakiin waa in lagu dhejiyaa qalab gaar ah - qoriga rivet (buugga, korontada).Rivetka noocaan ah wuxuu si gaar ah ugu habboon yahay munaasabadaha qulqulka halkaasoo aysan ku habboonayn isticmaalka rivets caadiga ah (kaas oo ay tahay in laga soo saaro labada dhinacba), sidaas darteed waxaa si weyn loogu isticmaalaa dhismayaasha, baabuurta, maraakiibta, diyaaradaha, mashiinnada, qalabka korontada, alaabta guriga iyo alaabta kale.Waxaa ka mid ah, nooca furan ee nooca furan ee madaxa pop rivets ayaa ah kuwa ugu badan ee loo isticmaalo, muraayadaha madaxa ee countersunk waxay ku habboon yihiin munaasabadaha qulqulka halkaasoo waxqabadka siman loo baahan yahay, iyo xirmooyinka pop-ga ah ee xiran waxay ku habboon yihiin munaasabadaha riveting halkaasoo culeys sare iyo qaar gaar ah. waxqabadka shaabadeynta ayaa loo baahan yahay.

Nooca Rivet ee la xidhay waxaa si gaar ah loogu talagalay in lagu duubo madaxa ciddiyaha ka dib marka la jeexjeexo, si uusan u daxalmin.Xiritaanka indho-la'aanta dhamaadka xiran ayaa aad ugu habboon codsiyada kala duwan ee leh shuruudaha biyuhu.Rivet-ga noocaan ah wuxuu leeyahay xoog-xiirid sare, iska caabin gariir iyo iska caabin cadaadis sare ah.

Talooyin loogu talagalay rivets indho la'aan ah Dooro:

Cabbirka daloolka qodista ee rivet waa min+0.1 max+0.2.

Wadarta dhumucda shaqada guud ahaan waa 45% - 65% dhererka dhererka Way fiicantahay inaadan dhaafin 60%.Intaa waxaa dheer, dhererka shaqada oo aad u gaaban ayaa sidoo kale dhib leh.Waxaa lagu talinayaa in 50% - 60% ay ku guuleystaan guud ahaan Haddii dhererka dhererku uu aad u dheer yahay, madaxa jeexjeexa ayaa aad u weyn, iyo usha rivet waa sahlan tahay in la leexiyo;Haddii dhererka dhererku aad u gaaban yahay, dhumucdiisuna waa mid aan ku filnayn, iyo qaabaynta madaxa rivet waa mid aan dhammaystirnayn, oo saameynaysa xoogga iyo cidhiidhiga.Ma wanaagsana haddii dhererka jeexjeexu uu aad u dheer yahay ama aad u gaaban yahay.Kaliya dhererka saxda ah ayaa gaari kara saameynta riveting ugu fiican.Tusaale ahaan, haddii dhumucda guud ee laba ama ka badan oo workpieces ay tahay 6mm, dhererka rivet waa inuu ahaadaa 9.23 -- 13.3 mm.Xaaladdan oo kale, waxa fiican in la isticmaalo rivet dheer 12mm.