Qalab

| Jirka | Aluminium (5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5%,3%-3.5%,5%) | ||

| dhame | La tolay | Midabka RAL rinji | ||

| Mandrel | Aluminium ● | Birta | Bir daxal laheyn | |

| dhame | La sifayn ● | Zinc Plated | La tolay | |

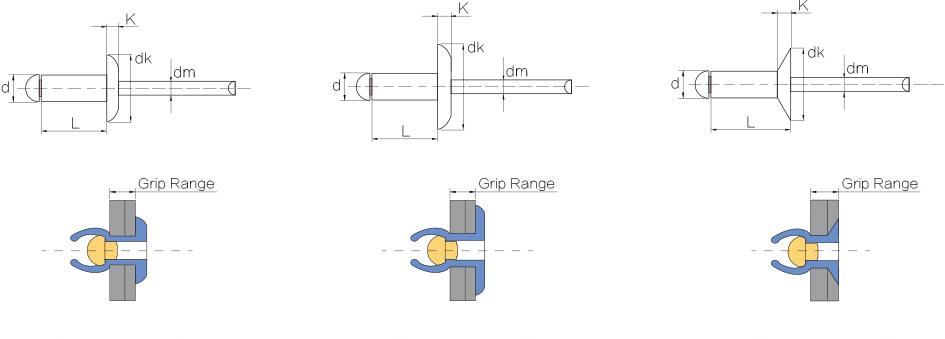

| Nooca Madaxa | Dome, CSK, Flange Weyn | |||

Tilmaamid

| D1 NOM. | QODON MAYA. & QODOBKA QOFKA | FANKA.CODE | XABSADA | L(MAX) | D NOM. | K MAX | P MIN. | SHARE LBS | Kacsan LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Codsiga

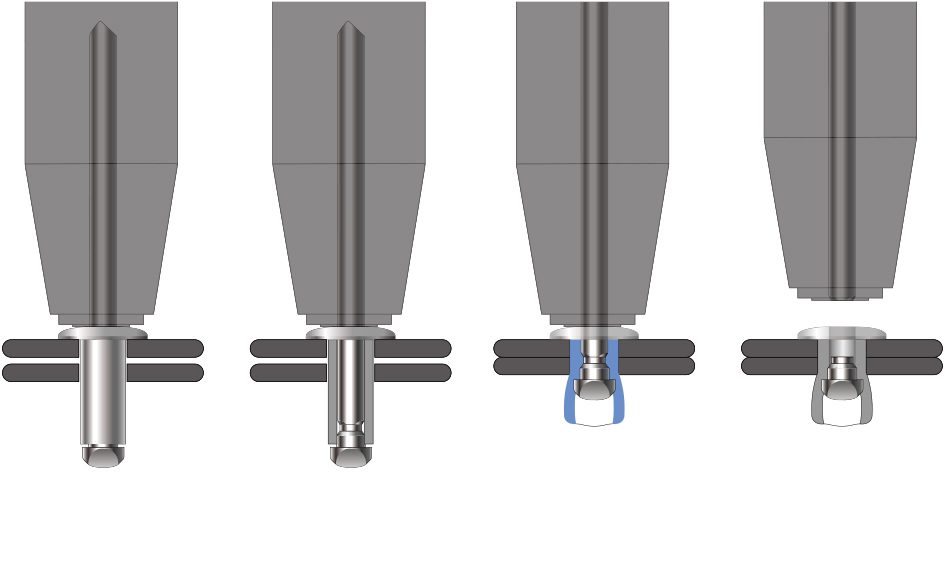

Aluminiumkayaga buuxa ee furan dhamaadka furan wuxuu isticmaalaa fiilooyinka aluminium tayo sare leh.Ka dib riveting, Marna ma miridhku.marka la barbardhigo rivets caadiga ah, xoojinta rivet waa yar yahay, sidaas darteed waxay ku haboon tahay in la isku xiro walxaha jilicsan. Aluminium pop rivets waxaa loo qaybin karaa rivet madaxa qubbad ah, rivets countersunk iyo rivet madax flange weyn.And aluminium aluminium ah ayaa leh doorasho badan. alu mg 2% 2.5% 3.5% iyo 5%(5052 5154 5056).

Fixpal nooca furan ee rivets pop ayaa leh faa'iidooyinka hawlgalka fudud, qulqulka wanaagsan, muuqaalka quruxda badan, sifooyinka sare ee jirka.Doorashada saxda ah ee riveting hal dhinac ah. Aluminium pop rivets ayaa si ballaaran loo isticmaali karaa baabuurta kala duwan, weelasha, wax soo saarka mishiinka, elektarooniga ah, qalabaynta, mashiinada cuntada, qalabka caafimaadka, dhismaha, qurxinta iyo meelaha kale ee lagu xidho.

Dhibaatooyinka iyo sababaha marka la isticmaalayo rivet indho la'aan:

1. Burrs: Ka dib riveting, mandrel jejebiyey leh burrs dhex mara godad rivet;ama godadka jeexjeexa ayaa ka soo baxa dibadda si ay u sameeyaan burka spatula.

Sababta burooyinka: dhexroorka mandrel waa yar yahay;walxaha rivet waa jilicsan;dhexroorka dalool qodista ee workpiece waa mid aad u weyn;Tilmaamaha xabka ee qoriga rivet waa mid aad u weyn;

2. Madaxa cididu wuu dhacaa: Ka dib marka la jiido, madaxa xudunta u ah lama duubi karo oo ka soo dhacayo rivetka.

Sababaha hoos u dhaca madaxa rivet ee xudunta u ah waa: dhexroorka daboolka ciddiyaha ayaa aad u weyn;dhumucdiisu waa ka gaaban tahay, dhumucdiisuna kuma eka.

3. dildilaaca jeexjeexa: ka dib jeexjeexa, jeexjeexa waa la garaacaa ama gebi ahaanba dillaacaa.

Sababaha dildilaaca jeexjeexa waa: adkaanta xad dhaafka ah ka dib marka la xoqdo ama daawaynta aan kuleylka lahayn, koofiyada udubdhexaadka ah ee ciddiyaha ayaa aad u weyn.