Qalab

| Jirka | Aluminium (5050 5052 5056) ● | Birta | Bir daxal laheyn | ||||

| dhame | La safeeyey, rinji | Zinc Plated | La tolay | ||||

| Mandrel | Aluminium | Birta ● | Bir daxal laheyn | Birta | Aluminium | Birta | Bir daxal laheyn |

| dhame | La tolay | Zinc Plated | La tolay | Zinc Plated | La tolay | Zinc Plated | La tolay |

| Nooca Madaxa | Dome, CSK, Flange Weyn | ||||||

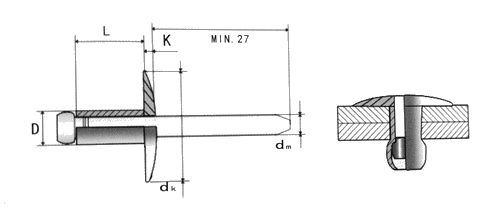

Tilmaamid

| D1 NOM. | QODON MAYA.& QODOBKA QOFKA | FANKA.CODE | XABSADA | L (MAX) | D NOM. | K MAX | P MIN. | SHARE LBS | Kacsan LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm | #30 3.3-3.4 | 1-AS42LF | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | 0.375" 9.5 | 0.065" 1.65 | 1.06" 27 | 120 530N | 150 670N |

| 1-AS43LF | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| 1-AS44LF | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| 1-AS45LF | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| 1-AS46LF | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| 1-AS48LF | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| 1-AS410LF | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | 1-AS52LF | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.468" 12.0 | 0.075" 1.90 | 1.06" 27 | 190 850N | 230 1020N |

| 1-AS53LF | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| 1-AS54LF | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| 1-AS56LF | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| 1-AS58LF | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| 1-AS510LF | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | 1-AS62LF | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.625" 16.0 | 0.092" 2.33 | 1.06" 27 | 260 1160N | 320 1430N |

| 1-AS63LF | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| 1-AS64LF | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| 1-AS66LF | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| 1-AS68LF | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| 1-AS610LF | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| 1-AS612LF | 0.626-0.750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| 1-AS614LF | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| 1-AS616LF | 0.876-1.000 | 22.5-25.4 | 1.200 | 30.5 | |||||||

| 1-AS618LF | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

Codsiga

Nooca flange ee waaweyn ee indhoolayaasha indhoolayaasha ah, dhexroorka madaxa rivetkan ayaa si weyn u kordhay marka la barbardhigo indhoolayaasha caadiga ah.Marka la jeexjeexo isku-xirayaasha, rivet-ku wuxuu leeyahay aag xiriir weyn, oogada taageerada xooggan, wuxuuna kor u qaadi karaa xoogga qulqulka.Madaxa garabka weyn ee pop rivet wuxuu u adkeysan karaa xiisad sare oo shucaac ah.

Warshadaha lagu dabaqi karo: Waxay ku habboon tahay in lagu dhejiyo jilicsan, qalabka dusha jilicsan iyo godad dhaadheer oo dheeraad ah.Madaxa flange weyn oo indho la'aan ah ayaa ilaalin kara alaabta jilicsan.

Waa maxay sababta mandrel rivet indho la'aan ah ayaa bannaanka u soo baxay oo la soo baxay inta lagu jiro isticmaalka rivets pop?

Inta lagu jiro habka loo isticmaalo rivets pop, macaamiishu inta badan waxay la kulmaan dhibaatooyin la xiriira koofiyadaha la soo bandhigay oo la soo saaray, kuwaas oo inta badan ay sababto isticmaalka khaldan.Hadda aan wadaagno qaar ka mid ah talooyin ku saabsan isticmaalka rivets pop.

1. Dooro sanbabada rivet ee u dhigma iyadoo loo eegayo qeexida iyo moodka rivet pop-ka.

2. Qoriga rivet waa in loo adeegsadaa cadaadiska hawada ku habboon.Guud ahaan waxaa lagu talinayaa in lagu isticmaalo cadaadiska hawada ee ka sarreeya 6kg/m2.Haddii cadaadiska hawadu uu aad u hooseeyo, madaxa xudunta u ah rivet ayaa laga yaabaa inuu si tartiib ah u habeeyo oo dibadda u baxo.

3. Walxaha qaybaha jeexjeexan waa in ay la socdaan tan jirka.

4. Daloolada riveting waa macquul.Daloollada riveting guud ahaan waa 0.1-0.2mm ka weyn dhexroorka dibadda ee jirka jeexan

5. Saddexda cidi ee ku jira sanka jeexjeexa waa in la beddelaa wakhti ku habboon ka dib marka la xidho.

Markaad fiiro gaar ah u yeelato tilmaamaha kor ku xusan, dhibaatada soo-gaadhista xudunta u ah iyo ka-noqoshada waa laga fogaan karaa.